Corrosion is a natural phenomenon which attacks metal by chemical or electrochemical action and converts it into a metallic compound, such as an oxide, hydroxide, or sulfate. Corrosion is to be distinguished from erosion, which is primarily destruction by mechanical action. The corrosion occurs because of the tendency for metals to return to their natural state.

Noble metals, such as gold and platinum, do not corrode since they are chemically uncombined in their natural state. Four conditions must exist before corrosion can occur (see Figure 2-1):

(1)

Presence of a metal that will corrode (anode);

(2) Presence of a dissimilar

conductive material (cathode) which has less tendency to corrode;

(3) Presence

of a conductive liquid (electrolyte); and

(4) Electrical contact between the

anode and cathode (usually metal to metal contact, or a fastener.

b.

Elimination of any one of these conditions will stop corrosion. An example

would be a paint film on the metal surface (see Figure 2-2).

Some metals (such as stainless steel and titanium), under the right conditions,

produce corrosion products that are so tightly bound to the corroding metal

that they form an invisible oxide film (called a passive film), which prevents

further corrosion. When the film of corrosion products is loose and porous

(such as those of aluminum and magnesium), an electrolyte can easily penetrate

and continue the corrosion process, producing more extensive damage than

surface appearance would show.

202.

DEVELOPMENT OF CORROSION.

a.

All corrosive attack begins on the surface of the metal. The corrosion process

involves two chemical changes. The metal that is attacked or oxidized undergoes

an anodic change, with the corrosive agent being reduced and undergoing a

cathodic change. The tendency of most metals to corrode creates one of the

major problems in the maintenance of the aircraft, particularly in areas where

adverse environmental or weather conditions exist.

b.

Paint coatings can mask the initial stages of corrosion. Since corrosion

products occupy more volume than the original metal, paint surfaces should be

inspected often for irregularities such as blisters, flakes, chips, and lumps.

203.

FACTORS INFLUENCING CORROSION.

a.

Some factors which influence metal corrosion and the rate of corrosion are the:

(1)

Type of metal;

(2) Heat treatment and grain direction;

(3) Presence of a

dissimilar, less corrodible metal (galvanic corrosion);

(4) Anode and cathode

surface areas (in galvanic corrosion);

(5) Temperature;

(6) Presence of

electrolytes (hard water, salt water, battery fluids, etc.);

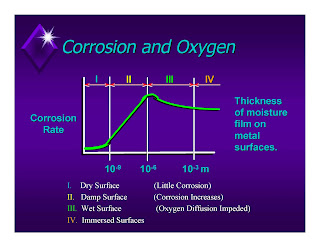

(7) Availability

of oxygen;

(8) Presence of different concentrations of the same electrolyte;

(9)

Presence of biological organisms;

(10) Mechanical stress on the corroding

metal; and

(11) Time of exposure to a corrosive environment.

b.

Most pure metals are not suitable for aircraft construction and are used only

in combination with other metals to form alloys. Most alloys are made up

entirely of small crystalline regions, called grains. Corrosion can occur on

surfaces of those regions which are less resistant and also at boundaries

between regions, resulting in the formation of pits and intergranular

corrosion. Metals have a wide range of corrosion resistance. The most active

metals (those which tend to lose electrons easily), such as magnesium and

aluminum, corrode easily. The most noble metals (those which do not lose

electrons easily), such as gold and silver, do not corrode easily.

c.

Corrosion is accelerated by higher temperature environments which accelerate

chemical reactions and allow greater moisture content at saturation in air.

d.

Electrolytes (electrically conducting solutions) form on surfaces when

condensation, salt spray, rain, or rinse water accumulate. Dirt, salt, acidic

gases, and engine exhaust gases can dissolve on wet surfaces, increasing the

electrical conductivity of the electrolyte, thereby increasing the rate of

corrosion.

e.

When some of the electrolyte on a metal surface is partially confined (such as

between faying surfaces or in a deep crevice), metal in this confined area

corrodes more rapidly than other metal surfaces of the same part outside this

area. This type of corrosion is called an oxygen concentration cell. Corrosion

occurs more rapidly than would be expected, because the reduced oxygen content

of the confined electrolyte causes the adjacent metal to become anodic to other

metal surfaces on the same part immersed in electrolyte exposed to the air.

f.

Slimes, molds, fungi, and other living organisms (some microscopic) can grow on

damp surfaces. Once they are established, the area tends to remain damp,

increasing the possibility of corrosion.

g.

Manufacturing processes such as machining, forming, welding, or heat treatment

can leave stresses in aircraft parts. This residual stress can cause cracking

in a corrosive environment when the threshold for stress corrosion is exceeded.

h.

Corrosion, in some cases, progresses at the same rate no matter how long the

metal has been exposed to the environment. In other cases, corrosion can

decrease with time, due to the barrier formed by corrosion products, or

increase with time if a barrier to corrosion is being broken down.

204.

FORMS OF CORROSION.

There

are many different types of corrosive attack and these will vary with the metal

concerned, corrosive media location, and time exposure. For descriptive

purposes, the types are discussed under what is considered the most commonly

accepted titles.

a.

Uniform Etch Corrosion.

Uniform

etch corrosion results from a direct chemical attack on a metal surface and

involves only the metal surface (see Figure 2-3).

On a polished surface, this type of corrosion is first seen as a general

dulling of the surface, and if the attack is allowed to continue, the surface

becomes rough and possibly frosted in appearance. The discoloration or general

dulling of metal created by exposure to elevated temperatures is not to be

considered as uniform etch corrosion.

b.

Pitting Corrosion.

The

most common effect of corrosion on aluminum and magnesium alloys is called

pitting (see Figure 2-4). It is first noticeable as a white or

gray powdery deposit, similar to dust, which blotches the surface. When the

deposit is cleaned away, tiny pits or holes can be seen in the surface. Pitting

corrosion may also occur in other types of metal alloys. The combination of

small active anodes to large passive cathodes causes severe pitting. The

principle also applies to metals which have been passivated by chemical

treatments, as well as for metals which develop passivation due to

environmental condition.

c.

Galvanic Corrosion.

Galvanic

corrosion occurs when two dissimilar metals make electrical contact in the

presence of an electrolyte (see Figure 2-5).

The rate which corrosion occurs depends on the difference in the activities. The

greater the difference in activity, the faster corrosion occurs. For example,

magnesium would corrode very quickly when coupled with gold in a humid

atmosphere, but aluminum would corrode very slowly in contact with cadmium. The

rate of galvanic corrosion also depends on the size of the parts in contact. If

the surface area of the corroding metal (the anode) is smaller than the surface

area of the less active metal (the cathode), corrosion will be rapid and

severe. When the corroding metal is larger than the less active metal,

corrosion will be slow and superficial. For example, an aluminum fastener in

contact with a relatively inert Monel structure may corrode severely, while a

Monel bracket secured to a large aluminum member would result in a relatively superficial

attack on the aluminum sheet.

d.

Concentration Cell Corrosion.

Concentration

cell corrosion is corrosion of metals in a metal to metal joint, corrosion at

the edge of a joint even though joined metals are identical, or corrosion of a

spot on the metal surface covered by a foreign material (see Figure 2-6).

Another term for this type of corrosion is crevice corrosion. Metal ion

concentration cells, oxygen concentration cells, and active passive cells are

the three general types of concentration cell corrosion.

(1)

Metal ion concentration cells.

The

solution may consist of water and ions of the metal which is in contact with

water. A high concentration of the metal ions will normally exist under faying

surfaces where the solution is stagnant, and a low concentration of metal ions

will exist adjacent to the crevice which is created by the faying surface. An

electrical potential will exist between the two points; the area of the metal in

contact with the low concentration of metal ions will be anodic and corrode,

and the area in contact with the high metal ions concentration will be cathodic

and not show signs of corrosion. Figure 2-6

illustrates metal ion concentration cell corrosion.

(2)

Oxygen concentration cells.

The

solution in contact with the metal surface will normally contain dissolved

oxygen. An oxygen cell can develop at any point where the oxygen in the air is

not allowed to diffuse into the solution, thereby creating a difference in

oxygen concentration between two points. Typical locations of oxygen

concentration cells are under either metallic or nonmetallic deposits on the

metal surface and under faying surfaces such as riveted lap joints. Oxygen

cells can also develop under gaskets, wood, rubber, and other materials in

contact with the metal surface. Corrosion will occur at the area of low oxygen

concentration (anode) as illustrated in Figure 2-6.

Alloys, such as stainless steel, which owe their corrosion resistance to

surface passivity, are particularly susceptible to this type of crevice

corrosion.

(3)

Active passive cells.

Metals

which depend on a tightly adhering passive film, usually an oxide for corrosion

protection, such as corrosion resistant steel, are prone to rapid corrosive

attack by active passive cells. The corrosive action usually starts as an

oxygen concentration cell. As an example, salt deposits on the metal surface in

the presence of water containing oxygen can create the oxygen cell. The passive

film will be broken beneath the dirt particle. Once the passive film is broken,

the active metal beneath the film will be exposed to corrosive attack. An

electrical potential will develop between the large area of the cathode

(passive film) and the small area of the anode (active metal). Rapid pitting of

the active metal will result as shown in Figure 2-6.

e.

Intergranular Corrosion.

Intergranular

corrosion is an attack along the grain boundaries of a material. Each grain has

a clearly defined boundary which, from a chemical point of view, differs from

the metal within the grain center. The grain boundary and grain center can

react with each other as anode and cathode when in contact with an electrolyte.

Rapid selective corrosion at the grain boundary can occur with subsequent

delamination (see Figure 2-7). High strength aluminum alloys such as

2014 and 7075 are more susceptible to intergranular corrosion if they have been

improperly heat treated and are then exposed to a corrosive environment.

f.

Exfoliation Corrosion.

Exfoliation

corrosion is an advanced form of intergranular corrosion where the surface

grains of a metal are lifted up by the force of expanding corrosion products

occurring at the grain boundaries just below the surface. The lifting up or

swelling is visible evidence of exfoliation corrosion (see Figures 2-8

and 2-9). Exfoliation is most prone to occur in wrought

products such as extrusions, thick sheet, thin plate and certain die forged

shapes which have a thin, highly elongated platelet type grain structure. This

is in contrast with other wrought products and cast products that tend to have

an equiaxed grain structure.

g.

Filiform Corrosion.

Filiform

corrosion is a special form of oxygen concentration cell corrosion or crevice

corrosion which occurs on metal surfaces having an organic coating system. It

is recognized by its characteristic wormlike trace of corrosion products

beneath the paint film (see Figures 2-10

and 2-11). Filiform occurs when the relative

humidity of the air is between 78 and 90 percent and the surface is slightly

acidic. Corrosion starts at breaks in the coating system and proceeds

underneath the coating due to the diffusion of water vapor and oxygen from the

air through the coating. Filiform corrosion can attack steel and aluminum

surfaces. The traces never cross on steel, but they will cross under one

another on aluminum which makes the damage deeper and more severe for aluminum.

If filiform corrosion is not removed and the area treated and a protective

finish applied, the corrosion can lead to intergranular corrosion, especially

around fasteners and at seams. Filiform corrosion can be removed using glass

bead blasting material with portable abrasive blasting equipment and/or

mechanical means such as buffing or sanding. Filiform corrosion can be

prevented by storing aircraft in an environment with a relative humidity below

70 percent, using coating systems having a low rate of diffusion for oxygen and

water vapors, and by washing aircraft to remove acidic contaminants from the

surface, such as those created by pollutants in the air.

205.

CORROSION AND MECHANICAL FACTORS.

Corrosive

attack is often aggravated by mechanical factors that are either within the

part (residual) or applied to the part (cyclic service loads). Erosion by sand

and/or rain and mechanical wear will remove surface protective films and

contribute to corrosive attack of underlying metal surfaces. Corrosive attack

that is aided by some mechanical factor usually causes the part to degenerate

at an accelerated rate compared to the rate at which the same part would

deteriorate if it were subjected solely to corrosive attack. Environmental

conditions and the composition of the alloy also influence the extent of

attack. Examples of this kind of alliance are stress corrosion cracking,

corrosion fatigue, and fretting corrosion.

a.

Stress Corrosion Cracking.

Stress

corrosion cracking is an intergranular cracking of the metal which is caused by

a combination of stress and corrosion (see Figures 2-12

through 2-14). Stress may be caused by internal or

external loading. Internal stresses are produced by nonuniform deformation

during cold working, by unequal cooling from high temperatures, and by internal

structural rearrangement involving volume changes. Internal stresses are

induced when a piece of structure is deformed during an assembly operation,

(i.e., during pressing in bushings, shrinking a part for press fit, installing

interference bolts, installing rivets, etc.). Concealed stress is more

important than design stress, because stress corrosion is difficult to

recognize before it has overcome the design safety factor. The level of stress

varies from point to point within the metal. Stresses near the yield strength

are generally necessary to promote stress corrosion cracking, but failures may

occur at lower stresses. Specific environments have been identified which cause

stress corrosion cracking of certain alloys. Salt solutions and seawater may

cause stress corrosion cracking of high strength heat treated steel and

aluminum alloys. Methyl alcohol hydrochloric acid solutions will cause stress

corrosion cracking of some titanium alloys. Magnesium alloys may stress corrode

in moist air. Stress corrosion may be reduced by applying protective coatings,

stress relief heat treatment, using corrosion inhibitors, or controlling the

environment. Shot peening a metal surface increases resistance to stress

corrosion cracking by creating compressive stresses on the surface which should

be overcome by applied tensile stress before the surface sees any tension load.

Therefore, the threshold stress level is increased. {Figure 2-13}

b.

Corrosion Fatigue.

Corrosion

fatigue is caused by the combined effects of cyclic stress and corrosion. No

metal is immune to some reduction in its resistance to cyclic stressing if the

metal is in a corrosive environment. Damage from corrosion fatigue is greater

than the sum of the damage from both cyclic stresses and corrosion. Corrosion

fatigue failure occurs in two stages. During the first stage, the combined

action of corrosion and cyclic stress damages the metal by pitting and crack

formation to such a degree that fracture by cyclic stressing will ultimately

occur, even if the corrosive environment is completely removed. The second

stage is essentially a fatigue stage in which failure proceeds by propagation

of the crack (often from a corrosion pit or pits) and is controlled primarily

by stress concentration effects and the physical properties of the metal.

Fracture of a metal part, due to fatigue corrosion, generally occurs at a

stress level far below the fatigue limit in laboratory air, even though the

amount of corrosion is relatively small. For this reason, protection of all

parts subject to alternating stress is particularly important, even in

environments that are only mildly corrosive.

c.

Fretting Corrosion.

Damage

can occur at the interface of two highly loaded surfaces which are not supposed

to move against each other. However, vibration may cause the surfaces to rub

together resulting in an abrasive wear known as fretting. The protective film

on the metallic surfaces is removed by the rubbing action. The continued

rubbing of the two surfaces prevents formation of protective oxide film and

exposes fresh active metal to the atmosphere. Fretting can cause severe pitting

(see Figure 2-15). Dampening of vibration, tightening of

joints, application of a lubricant, or installation of a fretting resistant

material between the two surfaces can reduce fretting corrosion.

d.

Heat Treatment.

Heat

treatment of airframe materials should be rigidly controlled to maintain their

corrosion resistance as well as to improve their essential mechanical

properties. For example, improper heat treatment of clad aluminum alloy may

cause the cladding to incur excessive diffusion because the solution heat

treatment is too long or at too high a temperature. This degrades the inherent

resistance of the cladding itself, and reduces its ability to provide

protection to the core aluminum alloy. Aluminum alloys which contain

appreciable amounts of copper and zinc are highly vulnerable to intergranular

corrosion attack if not quenched rapidly during heat treatment or other special

treatment. Stainless steel alloys are susceptible to carbide sensitization when

slowly cooled after welding or high temperature heat treatment. Post weld heat

treatments are normally advisable for reduction of residual stress.

e.

Hydrogen Embrittlement.

(1) Environmentally

induced failure processes may often be the result of hydrogen damage rather

than oxidation. Atomic hydrogen is a cathodic product of many electrochemical

reactions, forming during naturally occurring corrosion reactions as well as

during many plating or pickling processes. Whether hydrogen is liberated as a

gas, or atomic hydrogen is absorbed by the metal, depends on the surface

chemistry of the metal.

(2)

Atomic hydrogen, due to its small size and mass, has very high diffusivity in

most metals. It will therefore penetrate most clean metal surfaces easily and

migrate rapidly to favorable sites where it may remain in solution, precipitate

as molecular hydrogen to form small pressurized cavities, cracks or large

blisters, or it may react with the base metal or with alloying elements to form

hydrides.

(3)

The accumulation of hydrogen in high strength alloys often leads to cracking,

and this often occurs in statically loaded components several hours or even

days after the initial application of the load or exposure to the source of

hydrogen. Cracking of this type is often referred to as hydrogen stress

cracking, hydrogen delayed cracking, or hydrogen induced cracking. Similar

fracture processes can occur in new and unused parts when heat treatments or

machining have left residual stresses in the parts, and have then been exposed

to a source of hydrogen. For this reason, all processes such as pickling or

electroplating must be carried out under well controlled conditions to minimize

the amount of hydrogen generated.

206.

COMMON CORROSIVE AGENTS.

Substances

that cause corrosion of metals are called corrosive agents. The most common

corrosive agents are acids, alkalies, and salts. The atmosphere and water, the

two most common media for these agents, may act as corrosive agents too.

a.

Acids.

In

general, moderately strong acids will severely corrode most of the alloys used

in airframes. The most destructive are sulfuric acid (battery acid), halogen

acids (i.e., hydrochloric, hydrofluoric, and hydrobromic), nitrous oxide

compounds, and organic acids found in the wastes of humans and animals.

b.

Alkalies.

Although

alkalies, as a group, are generally not as corrosive as acids, aluminum and

magnesium alloys are exceedingly prone to corrosive attack by many alkaline

solutions unless the solutions contain a corrosion inhibitor. Particularly

corrosive to aluminum are washing soda, potash (wood ashes), and lime (cement

dust). Ammonia, an alkali, is an exception because aluminum alloys are highly

resistant to it.

c.

Salts.

Most

salt solutions are good electrolytes and can promote corrosive attack. Some

stainless steel alloys are resistant to attack by salt solutions but aluminum

alloys, magnesium alloys, and other steels are extremely vulnerable. Exposure

of airframe materials to salts or their solutions is extremely undesirable.

d.

The Atmosphere.

The

major atmospheric corrosive agents are oxygen and airborne moisture, both of

which are in abundant supply. Corrosion often results from the direct action of

atmospheric oxygen and moisture on metal, and the presence of additional

moisture often accelerates corrosive attack, particularly on ferrous alloys.

However, the atmosphere may also contain other corrosive gases and

contaminants, particularly industrial and marine environments, which are

unusually corrosive.

(1)

Industrial atmospheres contain many contaminants, the most common of which are

partially oxidized sulfur compounds. When these sulfur compounds combine with

moisture, they form sulfur based acids that are highly corrosive to most

metals. In areas where there are chemical industrial plants, other corrosive

atmospheric contaminants may be present in large quantities, but such

conditions are usually confined to a specific locality.

(2)

Marine atmospheres contain chlorides in the form of salt particles or droplets

of salt saturated water. Since salt solutions are electrolytes, they corrosively

attack aluminum and magnesium alloys which are vulnerable to this type of

environment.

e.

Water.

The

corrosivity of water will depend on the type and quantity of dissolved mineral

and organic impurities and dissolved gasses (particularly oxygen) in the water.

One characteristic of water which determines its corrosivity is the

conductivity or its ability to act as an electrolyte and conduct a current.

Physical factors, such as water temperature and velocity, also have a direct

bearing on the corrosivity.

(1)

The most corrosive of natural waters (sea and fresh waters) are those that

contain salts. Water in the open sea is extremely corrosive due to the presence

of chloride ions, but waters in harbors are often even more so because they are

contaminated by industrial waste.

(2)

The corrosive effects of fresh water varies from locality to locality due to

the wide variety of dissolved impurities that may be present in any particular

area. Some municipal waters (potable water) to which chlorine and fluorides have

been added can be quite corrosive. Commercially softened water and industrially

polluted rain water are usually considered to be very corrosive.

207.

MICRO-ORGANISMS.

a.

Microbial attack includes actions of bacteria, fungi, or molds. Micro-organisms

occur nearly everywhere. Those organisms causing the greatest corrosion

problems are bacteria and fungi.

b.

Bacteria may be either aerobic or anaerobic. Aerobic bacteria require oxygen to

live. They accelerate corrosion by oxidizing sulfur to produce sulfuric acid.

Bacteria living adjacent to metals may promote corrosion by depleting the

oxygen supply or by releasing metabolic products. Anaerobic bacteria, on the

other hand, can survive only when free oxygen is not present. The metabolism of

these bacteria requires them to obtain part of their sustenance by oxidizing

inorganic compounds, such as iron, sulfur, hydrogen, and carbon monoxide. The

resultant chemical reactions cause corrosion.

c.

Fungi are the growths of micro-organisms that feed on organic materials. While

low humidity does not kill microbes, it slows their growth and may prevent

corrosion damage. Ideal growth conditions for most micro-organisms are

temperatures between 68 and 104 °F (20 and 40 °C) and relative humidity between

85 and 100 percent. It was formerly thought that fungal attack could be

prevented by applying moisture proofing coatings to nutrient materials or by

drying the interiors of compartments with desiccants. However, some moisture

proofing coatings are attacked by mold, bacteria, or other microbes, especially

if the surfaces on which they are used are contaminated. Microbial growth

occurs at the interface of water and fuel, where the fungus feeds on fuel.

Organic acids, alcohols, and esters are produced by growth of the fungus. These

byproducts provide even better growing conditions for the fungus. The fungus

typically attaches itself to the bottom of the tank and looks like a brown

deposit on the tank coating when the tank is dry. The fungus growth may start

again when water and fuel are present.

d.

The spore form of some micro-organisms can remain dormant for long periods

while dry, and can become active when moisture is available. When desiccants

become saturated and unable to absorb moisture passing into the affected area,

micro-organisms can begin to grow. Dirt, dust, and other airborne contaminants

are the least recognized contributors to microbial attack. Unnoticed, small

amounts of airborne debris may be sufficient to promote fungal growth.

e.

Fungi nutrients have been considered to be only those materials that have been

derived from plants or animals. Thus, wool, cotton, rope, feathers, and leather

were known to provide sustenance for microbes, while metals and minerals were

not considered fungi nutrients. To a large extent this rule of thumb is still

valid, but the increasing complexity of synthetic materials makes it difficult

or impossible to determine from the name alone whether a material will support

fungus. Many otherwise resistant synthetics are rendered susceptible to fungal

attack by the addition of chemicals to change the material's properties.

f.

Damage resulting from microbial growth can occur when any of three basic

mechanisms, or a combination of these, is brought into play. First, fungi are

damp and have a tendency to hold moisture, which contributes to other forms of

corrosion. Second, because fungi are living organisms, they need food to

survive. This food is obtained from the material on which the fungi are

growing. Third, these micro-organisms secrete corrosive fluids that attack many

materials, including some that are not fungi nutrient.

g.

Microbial growth must be removed completely to avoid corrosion. Microbial

growth should be removed by hand with a firm nonmetallic bristle brush and

water. Removal of microbial growth is easier if the growth is kept wet with

water. Microbial growth may also be removed with steam at 100 psi and steam

temperatures not exceeding 150 °F (66 °C). Protective clothing must be used

when using steam for removing microbial growth.

208.

METALLIC MERCURY CORROSION ON ALUMINUM ALLOYS.

Spilled

mercury on aluminum should be cleaned immediately because mercury causes

corrosion attack which is rapid in both pitting and intergranular attack and is

very difficult to control. The most devastating effect of mercury spillage on

aluminum alloys is the formation of an amalgam which proceeds rapidly along

grain boundaries, causing liquid metal embrittlement. If the aluminum alloy

part is under tension stress, this embrittlement will result in splitting with

an appearance similar to severe exfoliation. X-ray inspection may be an effective

method of locating the small particles of spilled mercury because the dense

mercury will show up readily on the X-ray film.

209 -

299 RESERVED.